It’s Love Your Pet Day! While pet owners celebrate with treats and extra attention, manufacturers producing those treats have a different focus, ensuring quality and compliance in pet food manufacturing. Pet food must meet strict safety and nutritional standards, with any lapse potentially leading to recalls, financial losses, and risks to animal health.

Unlike human food, pets eat the same meals every day. This makes consistency essential, not just for nutrition but for digestive health and overall well-being. Manufacturers must ensure that every bag of kibble or tin of wet food contains the right balance of ingredients and is free from contaminants. Achieving this at scale while staying compliant with industry regulations requires robust quality control processes and precise compliance tracking.

Why Compliance is Pet Food Manufacturing Matters

The pet food industry is subject to strict regulatory frameworks that vary by region. In the UK and EU, manufacturers must follow FEDIAF (European Pet Food Industry Federation) guidelines, while in the US, compliance falls under AAFCO (Association of American Feed Control Officials) and FDA regulations. These standards dictate:

- Ingredient safety and sourcing requirements

- Nutritional content guidelines

- Manufacturing hygiene standards

- Product labelling and traceability rules

Regulations are in place to protect pets and build consumer trust. Pet food recalls, while less common than in human food production, can be devastating when they happen. Issues like contamination, nutrient imbalances or mislabelled allergens can lead to health risks, lost revenue and reputational damage.

Using Compliance Software to Support Pet Food Manufacturing Standards

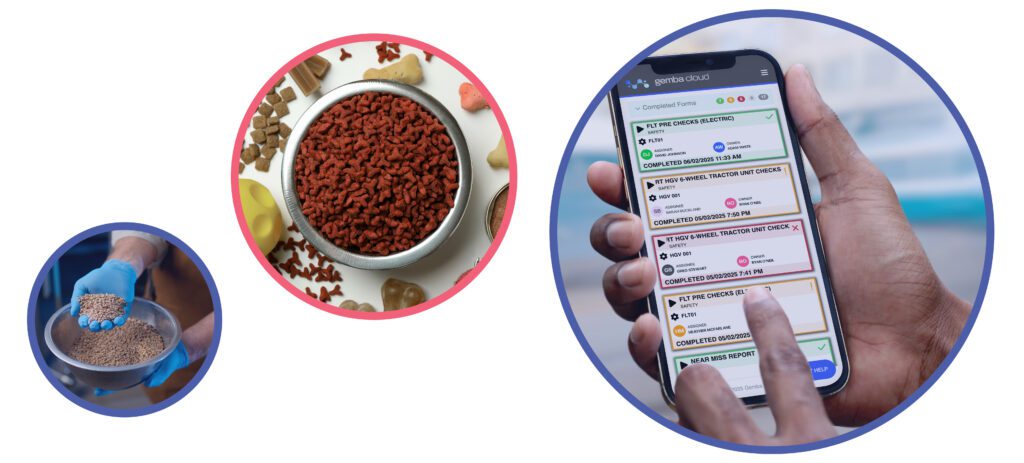

With so many moving parts in the production process, manual compliance tracking leaves too much room for error. A missed check, an incomplete record or a delay in identifying a deviation could lead to costly consequences.

Digital compliance tools provide a structured way to manage quality and regulatory requirements by:

- Tracking every step in production to ensure adherence to safety and hygiene protocols

- Digitising quality control checklists to reduce reliance on manual paperwork

- Flagging potential issues early through real-time data collection

- Improving traceability, making it easier to pinpoint and resolve problems before they escalate

Some manufacturers have avoided expensive recalls by catching formulation errors or contamination risks early using compliance software. Automated record-keeping and audit trails not only streamline internal processes but also make external inspections smoother.

Achieving Compliance in Pet Food Manufacturing for Safer Products

Regulations in pet food manufacturing continue to evolve, with growing scrutiny on ingredient sourcing, labelling accuracy and contamination prevention. Manufacturers that invest in robust compliance systems are better positioned to maintain product integrity while reducing risk across the supply chain.

With the right compliance tools in place, pet food manufacturers can stay ahead of regulations, protect their brand and most importantly, ensure the safety and quality of every product that reaches pet owners.

Learn more with Gemba Compliance?

To see how Gemba Compliance can help you, contact us or schedule a demo today.